Global trade relies on rugged steel boxes built to ISO standards, which shift seamlessly between ship, rail, and truck. Affordable cargo shipping containers let everything from raw materials to fine art travel safely and at scale. In this concise guide, you’ll discover which products most often ride inside these containers, why their uniform design excels at protecting cargo, how to choose the right box for cost-effective, damage-free transit, and how specialist art logistics crews customize units to safeguard priceless works bound for exhibitions and fairs.

Core Cargo Categories

Before smartphones, sneakers, or museum pieces ever make it into a box, the world’s most fundamental building blocks have to move in staggering volumes. Dry 20-ft and 40-ft containers shoulder much of that load, carrying everything from construction lumber to industrial feedstocks across oceans and continents. Their sealed steel walls keep moisture and grime out, while reinforced plywood floors handle brutal point loads that would splinter lesser equipment. Inside these workhorse units are:

Consumer Goods

Everything shoppers click “add to cart,” from flat-pack furniture to televisions and skin-care sets, typically leaves the factory in 40 ft high-cube containers. Lockable steel walls deter pilferage, while the extra interior height lets brands consolidate thousands of retail items in a single move.

Construction Products

Engineered flooring, plywood, steel beams, and site machinery cross oceans every day. Cartoned boards and tiles ride in dry boxes. Oversized generators, excavator arms, or prefabricated facades are lashed onto flat racks or slid into open-tops.

Specialized & High-Care Items

Electronics, auto parts, laboratory equipment, or porcelain tiles need controlled handling. Dry containers lined with desiccant packs fend off humidity; reefers (refrigerated boxes) maintain a tight –25 °C to +25 °C window for pharmaceuticals, craft beer, or fresh produce.

Agricultural & Food Commodities

Grain, fertilizer, animal feed, bottled wine, and canned products all have a sealed atmosphere in a container. Dry bulk is transported in lined boxes; perishables go by reefers, whose temperature and humidity are controlled throughout the entire passage.

Premium Art Handling in Containers

Worldwide exhibitions and art shows demand more than a standard freight service. Skilled art logistics teams blend museum-level care and containerized transportation so that irreplaceable artwork remains secure, compliant, and show-ready.

Domestic & International Shipping

Works of art, sculpture, and mixed-medium artwork travel in temperature- and climate-controlled reefers or air-ride trucks at 20 °C ± 2 ° and 50 % RH, whether a short urban drive or a transoceanic shipment. In-house personnel arrange all CARNETS ATA, CITES documents, and custom forms if needed so that borders pass through smoothly.

State-of-the-Art Storage

CCTV-monitored warehouses offer individually alarmed, microclimate cells. Every work is checked, photographed, and issued a digital condition report that clients can view on demand.

Cross-Country Art Shuttle

Dedicated, fixed-route art shuttle trucks circulate on a set schedule among the nation’s leading art hubs, pooling shipments from galleries, museums, and private collectors. By sharing space, clients cut costs while still receiving full white glove handling and the gentle ride of air-ride suspension.

Professional Art Installation

Specialist crews unpack, condition-check, and hang, mount, or plinth each piece to curator's specifications down to final alignment and exhibition lighting.

Auction House Pick-Up

Logisticians coordinate directly with Christie’s, Sotheby’s, and regional auction houses. Newly acquired lots are photographed, custom-crated, and sealed under joint witness before heading to storage, restoration, or the buyer’s door.

Why Containers Fit the Job

- Versatility – Standard 20 ft (~33 m³) and 40 ft (~67 m³) boxes cover most weight-to-volume ratios, while reefers, open-tops, and flat-racks handle cold-chain or out-of-gauge loads.

- Durability – Corten-steel walls shrug off salt spray, forklift bumps, and monsoon rains, outperforming break-bulk stowage.

- Intermodal Efficiency – One seal applied at origin stays intact through every port, rail yard, and distribution center, cutting handling costs and risk of theft.

- Global Standardization – Cranes, chassis, and depots worldwide are built around ISO dimensions, making routing predictable and quick.

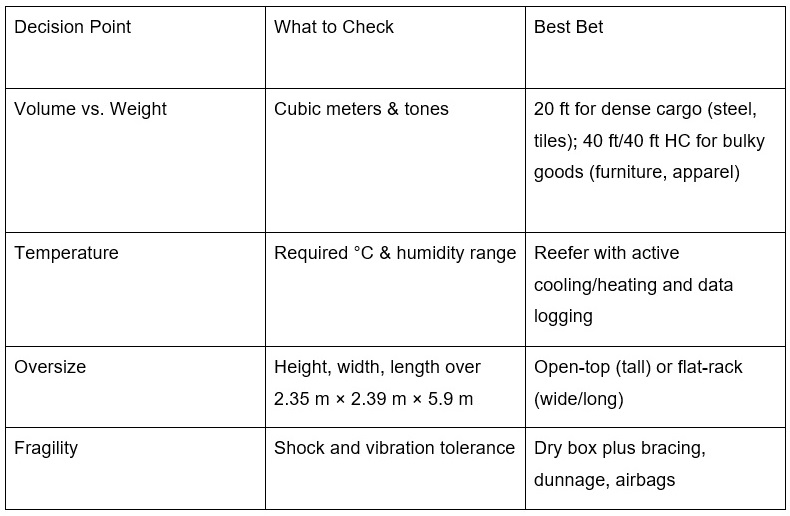

Choosing the Right Box

Smart Packing & Loading Tips

- Start with robust, undamaged pallets, then stretch-wrap the load so that forklifts can handle each unit without collapse or snagging.

- Spread the load throughout the entire surface of the floor; a constant load prevents a container's wooden decking from being perforated by point pressure.

- For unusually weighty objects, block and brace using hardwood and hold every such piece in position with steel strapping so that nothing shifts when being transported.

- Humidity protection: place desiccant pouches or full liners, especially relevant to fabrics, paper goods, microchips, and moisture-sensitive goods.

- End with smart stacking. Keep bulk, weighty cartons at top deck levels and seed dense, compact crates low down and dead-center to guarantee stability.

Shipping Containers: The Backbone of Modern Logistics

Containers, trucks, planes, or warehouses are the silent engines that keep global logistics running. Because every container meets ISO specs, a factory in Shenzhen and a curator in Miami can speak one seamless transport language, while specialist handlers add museum-grade safeguards on top.

The message is clear: pair volume, sensitivity, and sheer size of cargo with an appropriate container, secure it down as appropriate, and obtain proper expertise whether it be a mainstream freight forwarder or white glove art logistics team to get it all delivered safely, on time, and prepared for its next leg.