American pallet standards meet the logistics and transportation industry requirements. They ensure compatibility with automated systems and comply with international trade regulations. Repackify can help you meet these requirements and save your wallet. Their website has a huge number of used pallets for sale, among which you can always choose an offer near you, as well as organize the transportation of the selected items to your facility or warehouse.

Main Size Standards

GMA Pallets: Industry Benchmark

The most common standard is the GMA (Grocery Manufacturers Association) 48×40 inches (122×102 cm), which represents 30% of the market. The construction includes:

- 7 top boards with a thickness of ½ inch (13 mm), including two edge boards 5.5 inches (14 cm) wide and five center boards 3.5 inches (9 cm) each.

- 5 bottom boards with a similar distribution, providing four-way entry for forklifts.

- Load capacity of up to 2,500 pounds (1,134 kg) dynamic and 6,000 pounds (2,722 kg) static load.

Example: The PWU-4840-GMA-SA pallet weighs 55 pounds (25 kg) and can be stacked up to 5 tiers high.

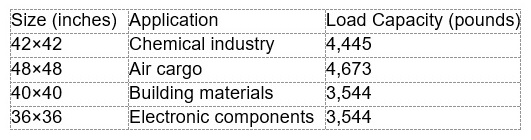

Alternative Sizes

These sizes are regulated by NWPCA (National Wooden Pallet and Container Association) standards.

Quality Classification

Grade A and Grade B

- Grade A (Premium): Pallets without cracks, chips, or fungal damage. Up to 3 repair plates allowed. Used for export.

- Grade B: Have minor defects (chips up to 2 inches), suitable for internal logistics. Reduce costs by 15-20% compared to new ones.

Evaluation criteria include corner block integrity, absence of protruding nails, and board thickness compliance.

Treatment Requirements

ISPM15 Phytosanitary Standards

All wooden pallets for international shipments must undergo:

- Heat treatment at +133°F for 30 minutes.

- Marking with the IPPC symbol indicating country code and treatment method (HT — heat treatment).

Plastic pallets are exempt from these requirements due to their non-porous structure that prevents pathogen absorption.

Industry Specifications

Food Industry

GMA pallets for the food industry additionally must:

- have rounded edges for easier washing;

- be made from hardwood (maple, oak) with moisture content ≤19%;

- undergo weekly disinfection with hydrogen peroxide-based solutions.

Pharmaceuticals and Chemicals

Pallets with antistatic coating and RFID tags for temperature monitoring are used.

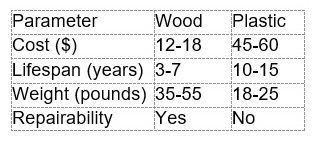

Material Comparison

Requirements for Pallets from US Agencies

Requirements include specifications for dimensions, materials, strength, pest treatment, and hygienic standards depending on the type of goods being transported.

Food and Drug Administration (FDA):

- Requires pallets for food products to be made from materials that don't contaminate food

- Regulates sanitary standards for pallets used in food transportation

- Requires treatment of wooden pallets to prevent contamination

United States Department of Agriculture (USDA):

- Establishes phytosanitary requirements for wooden pallets

- Requires wooden pallets to be treated according to ISPM-15 standard for international shipments

Department of Transportation (DOT):

- Regulates cargo transportation safety, including requirements for securing loads on pallets

- Establishes requirements for maximum load and weight distribution

Occupational Safety and Health Administration (OSHA):

- Establishes rules for safe handling of pallets in the workplace

- Regulates procedures for loading, unloading, and stacking palletized cargo

Grocery Manufacturers Association (GMA):

- Establishes dimensions for standard pallets in the food industry (48"x40")

- Defines requirements for pallet strength and quality

American National Standards Institute (ANSI) in conjunction with MHI (Material Handling Industry):

- Develops MH1 standards for pallets

- Establishes requirements for dimensions, materials, and construction

Market Trends

By 2025, hybrid pallets (wood + plastic) are expected to reach 25% of the market. This change will cut maintenance costs by 30%. IoT sensors for cargo integrity will soon be standard in pharmaceutical shipments.

Conclusion

US pallet standards combine dimensional uniformity and flexibility for a variety of industries. The GMA 48×40 inch standard shows how effective centralized standardization can be.

In addition, tightening environmental regulations are pushing a shift to reusable plastic options.

However, the issue of price still leaves wooden pallets in the lead for most business and shipping categories where there are no stringent requirements from agencies such as the FDA.