Do you know what a distribution center is? Chances are, you have seen one before, but you may not know what it does. A distribution center is a facility that is used to store and distribute products to retailers and consumers. They are often located near airports or shipping ports so that products can be shipped quickly and easily. There are many things that go into the operation of a distribution center, and in this blog post, we will discuss six of them.

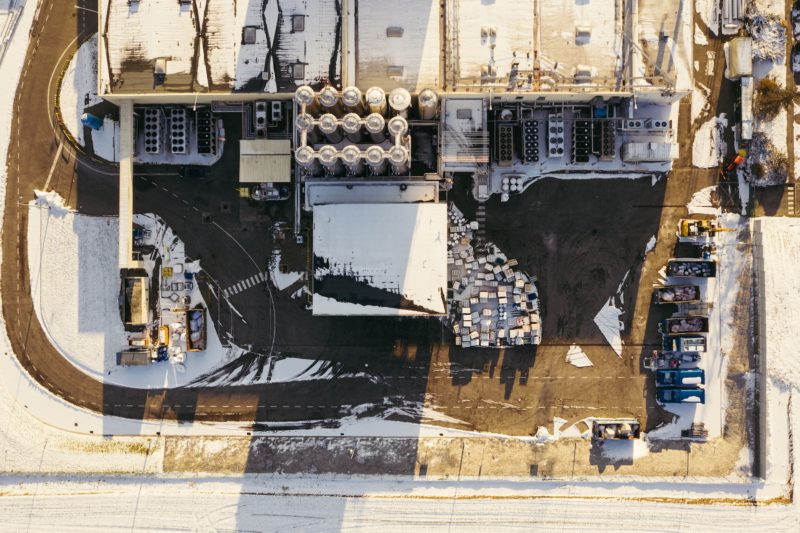

1. Distribution centers are often huge facilities

The average distribution center is about the size of four football fields, and some can be even larger. This is because they need a lot of space to store all the products they distribute. Often, these products are stored on shelves that are several stories high. Distribution centers usually have aisles that are wide enough for forklifts to drive through so that products can be easily moved around. On the other hand, you should know that there is a difference between a warehouse and a distribution center as well. A warehouse is used to store products, while a distribution center is used to distribute them. You may be wondering how all these products get into the distribution center in the first place. Usually, they come from manufacturers who ship them to the distribution center by truck or train. From there, they are stored until they are needed.

2. They use a lot of technology

Distribution centers are very high-tech places. They use computers to track all the products that come in and go out. This information is used to ensure that products are always in stock and delivered to the right place at the right time. Often, distribution centers use robots to move products around. These robots can work 24 hours a day and never get tired.

Distribution centers are also using more and more automated machines to sort products. These machines can sort products by size, weight, or even color. This helps make sure that products are put on the right shelves and that they are easy to find when someone needs them.

3. They need to be close to transportation

One of the most important things for a distribution center is its location. It needs to be close to transportation so that products can be easily shipped out. Often, distribution centers are located near airports or shipping ports. This allows manufacturers to quickly and easily ship their products to the distribution center. From there, the products can be sorted and stored until they are needed. For example, if a product is needed in New York, it can be shipped from the distribution center to the store in just a few days.

4. Location is very important

Location is also important for distribution centers because they need to be close to the retailers that they are supplying. This way, products can be easily delivered to stores when they are needed. Often, distribution centers will have their own fleet of trucks that they use to deliver products to stores. This helps ensure that products are delivered on time and that they do not get damaged in transit. Moreover, retailers can also come to the distribution center to pick up products themselves. This is often done for larger orders.

5. They need to be able to store a lot of products

Another important thing for distribution centers is that they need to be able to store a lot of products. This is because they need to have products in stock so that they can be shipped out as soon as they are needed. Often, distribution centers have shelves that are several stories high. This helps make sure that they have enough space to store all the products they need.

Distribution centers also need to have a lot of loading docks. These are places where trucks can pull up and load or unload products. Often, there are several loading docks so that multiple trucks can be loaded or unloaded at the same time. For instance, if a store needs a lot of products, the distribution center can send out multiple trucks to make sure that they get everything they need.

6. They employ a lot of people

Finally, you may be surprised to learn that distribution centers employ a lot of people. This is because there is a lot of work that needs to be done in order to keep the center running smoothly. There are workers who unload the trucks and put the products away. There are also workers who pick up the products and pack them up for shipping. In addition, there are workers who maintain the machines and the computers that are used to track everything. As you can see, there is a lot that goes on in a distribution center.

Distribution centers are an important part of the supply chain. They help make sure that products are always in stock and that they are delivered on time. Without distribution centers, it would be very difficult for stores to get the products they need. Next time you are in a store, take a moment to think about all the work that went into getting the products there.